The Product Carbon Footprint Calculator: Life cycle assessment for your products

RUCH NOVAPLAST has developed a flexible and transparent Product Carbon Footprint (PCF) calculator. This tool enables companies to determine the life cycle assessment for individual products made of EPP and to communicate this to their customers and partners – a real competitive advantage!

A product carbon footprint (PCF) is a climate balance at product level, in which direct and indirect greenhouse gas emissions during the product life cycle are considered. RUCH NOVAPLAST has developed a tool that supports companies in carrying out a PCF calculation for their molded parts made of EPP at material, technology and process level.

We offer our customers the opportunity to create and evaluate the CO₂ emissions of their products.

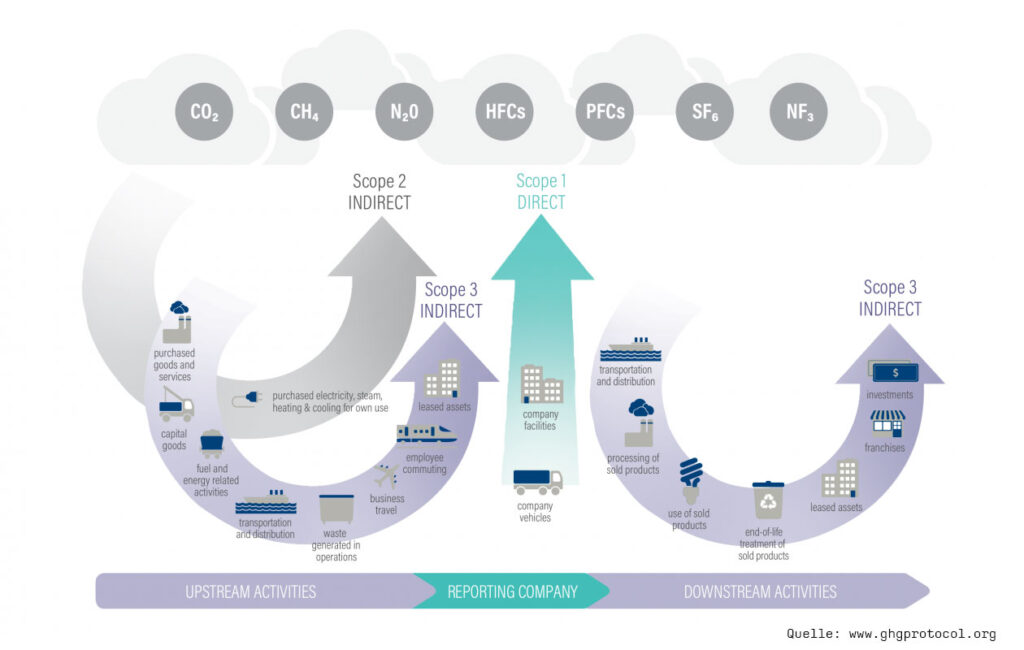

Our holistic approach across all three scopes

We consider all three scopes in our analysis, from raw material extraction (cradle) to the factory gate, taking into account all phases of the product life cycle in between:

- Scope 1 – Production & manufacturing:

covers direct emissions from own or controlled sources - Scope 2 – Energy:

covers indirect emissions from the generation of purchased electricity, steam, heat and cooling - Scope 3 – Upstream processes:

includes all other indirect emissions generated in a company’s value chain

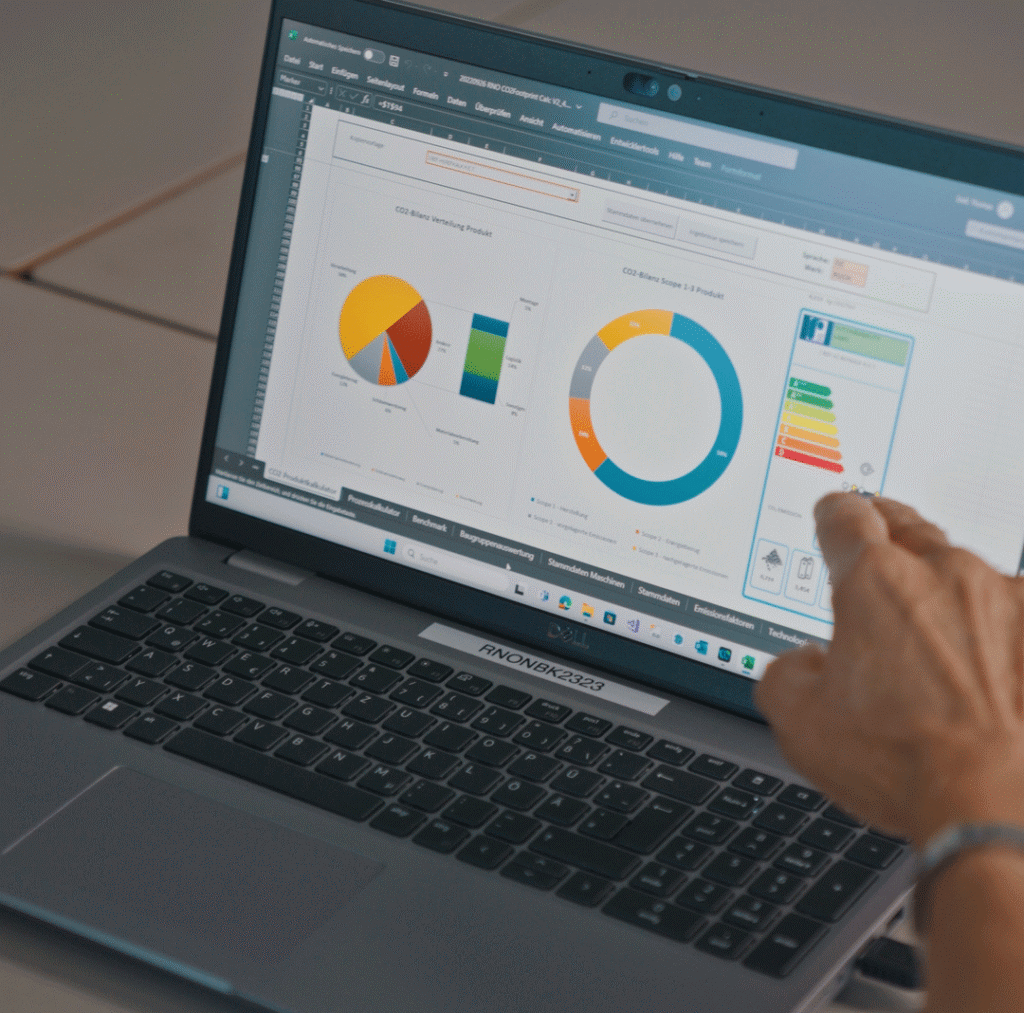

Calculation of the PCF

We measure the CO₂ emissions of a component as part of the product carbon footprint. The basis for this is an extensive collection of data that we have been able to build up thanks to our many years of experience in measuring and analyzing our processes.

Before the actual calculation, we record all relevant parameters of the component, e.g. material type, density and volume. Based on this data, we carry out a step-by-step assessment of the emission sources: First Scope 1 (process and fuel-related emissions), then Scope 2 (purchased energy) and finally Scope 3 (upstream and downstream emissions from the entire value chain).

Decades of project experience and a database of measured values to improve energy efficiency, the equipment of our machinery and energy generation with the necessary measurement technology to create a comprehensive energy balance are essential for the calculation. All of this knowledge has been implemented in the technology models of the PCF calculator in order to determine the most realistic emission factors possible based on our technologies and processes. The solution is rounded off with a process simulator that can also calculate consumption values and therefore CO₂ emissions when a product is in the inquiry phase, i.e. when there is no measurable consumption yet. These are subsequently measured and the calculation is validated with a new version index.

Identify optimization potential

Once the CO₂ emissions have been determined, we can identify various optimization potentials and show solution approaches and benchmarks for an effective reduction of CO₂ emissions. From optimizing tool efficiency to selecting suitable particle foam materials, we can help you understand and minimize the impact on your product’s carbon footprint.

Various factors can influence the life cycle assessment of an EPP molded part to varying degrees:

- Tools: The efficiency of the tool plays a central role in the production of a molded part made of particle foam. Our H.E.T. tools combine state-of-the-art technologies and optimized production processes

- Energy efficiency of energy generation: The way in which energy is generated for the production process has a direct impact on CO₂ emissions. The use of renewable energies can make a significant contribution to reducing emissions here.

- Particle foam material: The choice of particle foam material for the molded part also has an impact on the PCF. The use of recycled or bio-based materials can reduce the environmental impact.

- Process efficiency: Efficient production processes that minimize waste and optimize resource consumption reduce carbon emissions.

- Component size: The size of the molded part directly influences the amount of material and energy required for production.

- Delivery distance: The distance between production sites, suppliers and end customers has a significant impact on transportation emissions. Local production and short delivery routes can reduce CO₂ emissions.

- Annual quantity: The quantity of molded parts produced per year has a direct impact on total CO₂ emissions. High production efficiency and demand-driven production can reduce the environmental impact per unit.