ETPU: the flexible energy source for robust applications

Expanded thermoplastic polyurethane (ETPU) is an innovative lightweight material that impresses with its unique properties, such as 100% energy storage, high flexibility and elasticity. Compared to other materials, ETPU is particularly abrasion-resistant, which makes it ideal for demanding applications. Its outstanding flexibility makes the particle foam an ideal solution for products that offer optimum energy return or provide efficient cushioning.

Thanks to its robustness against abrasion and its soft-touch properties, ETPU remains efficient even in harsh environments. Its properties make ETPU the perfect choice for applications that require both flexibility and durability.

When energy absorption and rebound are crucial: ETPU

ETPU opens up a wide range of applications thanks to its exceptional combination of elasticity, lightness and durability. The particle foam is convincing wherever comfort, energy conversion and durability are required. Thanks to its high degree of freedom of form, components can be produced for a wide range of industries. Here is a selection of application areas for ETPU:

- Boost soles for sports shoes and insoles

- Vibration decoupler

- Damping elements

- Protectors and knee pads

- Lightweight parts in the automotive industry

- Core material in leisure and sports applications,

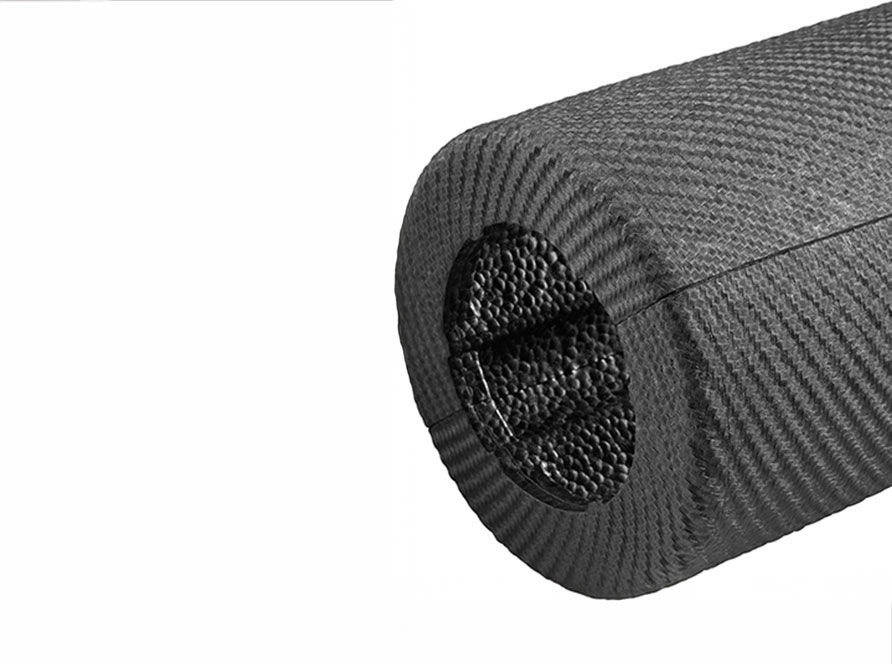

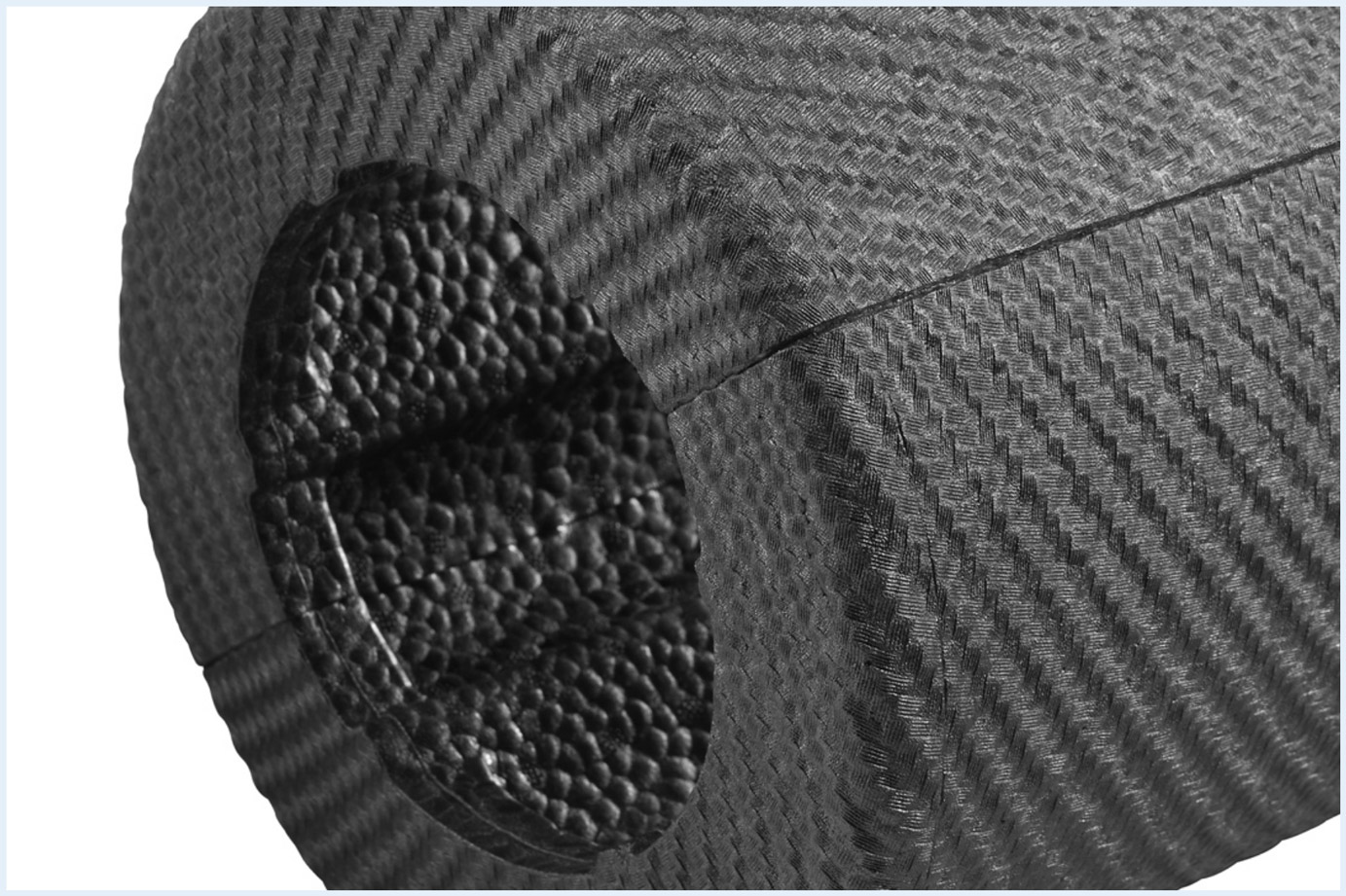

such as bicycle saddles, fascia rollers, airless bicycle tires, padel tennis rackets and toys - Damping mats

- Sports floors

Energy absorption, intermediate storage and rebound:

the most important properties of ETPUs

Expanded thermoplastic polyurethane combines a number of advantageous properties, making it interesting for a wide range of applications. Here is a summary of the most important material properties:

Enormous elasticity

The particle foam is super elastic and light at the same time.

Dimensional stability

Even under heavy loads, ETPU remains dimensionally stable and reliably returns to its original shape.

Dynamic cushioning and comfort

ETPU reliably absorbs shocks, even when high forces are applied, thus relieving pressure on the joints and spine in sports, for example.

Abrasion resistance

ETPU is highly abrasion-resistant and durable.

Elastic resilience

The material is extremely resilient. It absorbs the energy, stores it briefly and returns it (“rebound”) – a property that not only runners appreciate!

High weather resistance

ETPU copes well with UV, moisture and temperature changes.

Temperature resistance

Expanded thermoplastic polyurethane remains functional over a wide temperature range – even at low temperatures.

Lightweight

Thanks to its closed-cell structure, ETPU is very light and enables stable components with low density.

Chemical and oil resistance

The material is resistant to many chemicals and oils.

Versatile design

Modern manufacturing processes allow complex components to be produced with high precision.

The material ETPU

BASF revolutionized the footwear industry several years ago with its ETPU material Infinergy®.

In the form of the “Energy Boost” sole, the Infinergy® molded parts ensure a comfortable fit and also deliver excellent running properties. The enormous resilience of the material ensures that the sole springs back into its original shape immediately after compression, allowing runners to expend less energy.

The special cushioning properties and outstanding resilience of the material are also utilized in leisure and safety shoes. As insoles, they provide relief for the spine and protect the joints.

The high durability of ETPU and the low abrasion values are further advantages when used as shoe soles.

ETPU – recyclable, durable and pollutant-free

ETPU is based on Elastollan (TPU), is thermoplastic and can be fully recycled.

In this process, the end-of-life product is first mechanically shredded, while the chemical structure of the material is retained. The material residues are then melted again and re-extruded and expanded. This mechanical recycling process can be repeated as often as required in the interests of the circular economy.

Naturally compliant with standards

Expanded thermoplastic polyurethane complies with the RoHS Directive and does not contain any hazardous substances.

Frequently asked questions about ETPU: in a nutshell

In our FAQ section, we provide you with answers to questions about ETPU that we have come across several times. If you have any further questions, please feel free to contact us personally at any time.

In principle, yes. ETPU stands for expanded thermoplastic polyurethane. Infinergy® is the brand name of BASF.

ETPU springs back almost completely after loading instead of deforming or even absorbing the energy and breaking in the process. It remains very elastic in the long term, which means that cushioning is maintained for longer.

The same processing machines can be used for processing ETPU as for EPP foaming.

The best known application is certainly as boost soles for sports shoes and insoles. ETPU is also used as a core material in other leisure and sports applications, such as bicycle saddles, fascia rollers, paddle tennis rackets and toys. We also produce technical molded parts for protectors, as well as damping elements and lightweight construction solutions.

Yes, ETPU is thermoplastic, so it is fully recyclable and complies with the RoHS Directive. It is also very durable, which means that products can be used for longer and less waste is produced.

No. ETPU is free from harmful substances in accordance with current standards (e.g. RoHS-compliant) and is safe to use.

The material is currently available in white and black. Individual colors are technically feasible, but at the same time tied to large minimum order quantities.

Expanded thermoplastic polyurethane remains functional from approx. -20 °C to +80 °C.

Yes, the material variants differ in color and bead size/bulk density, which are selected depending on the application.

Yes, as it is free of harmful substances and offers a high level of safety through cushioning and break resistance, it is also used in toys and sports articles.