EPPE: Precision and safety for electronics applications

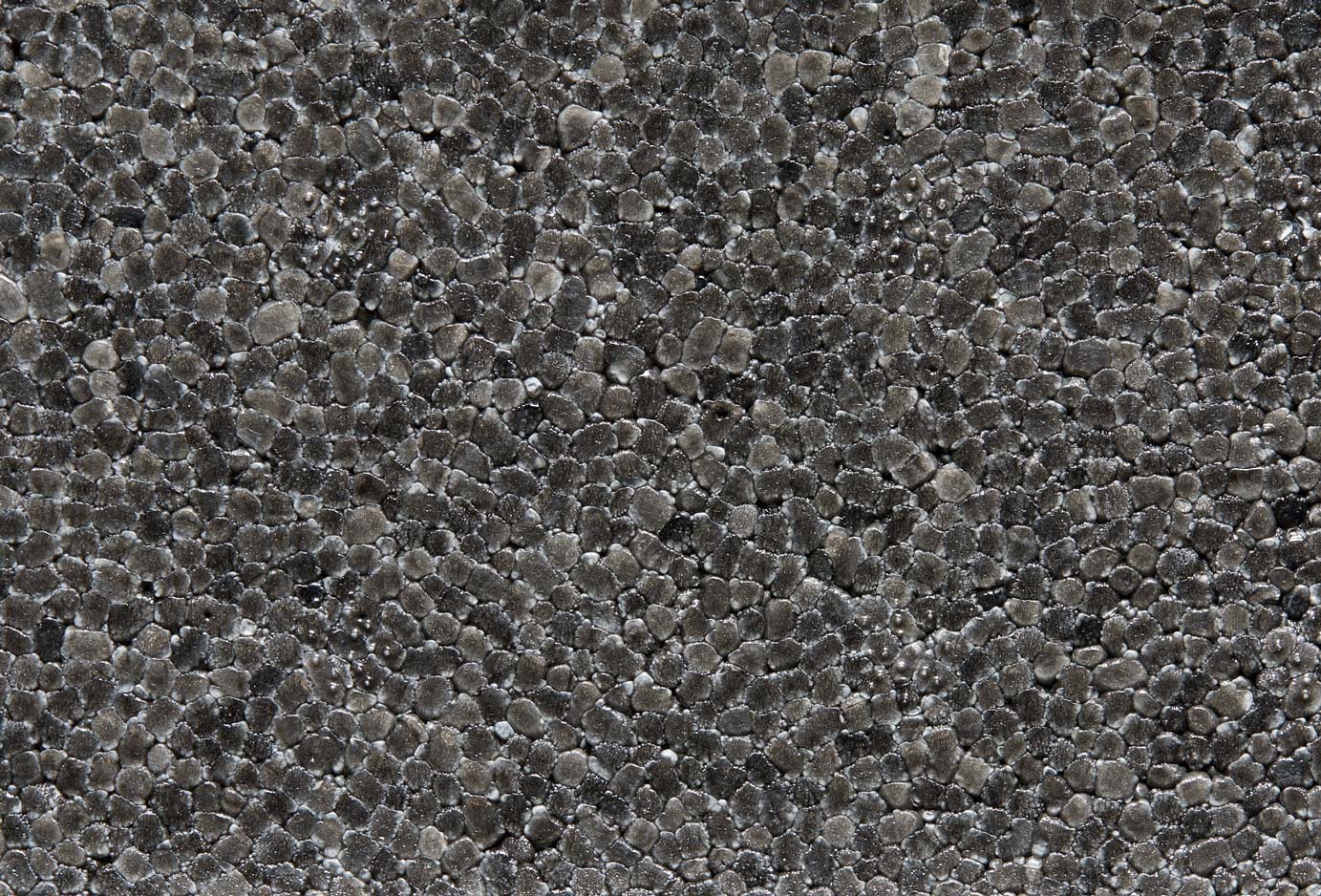

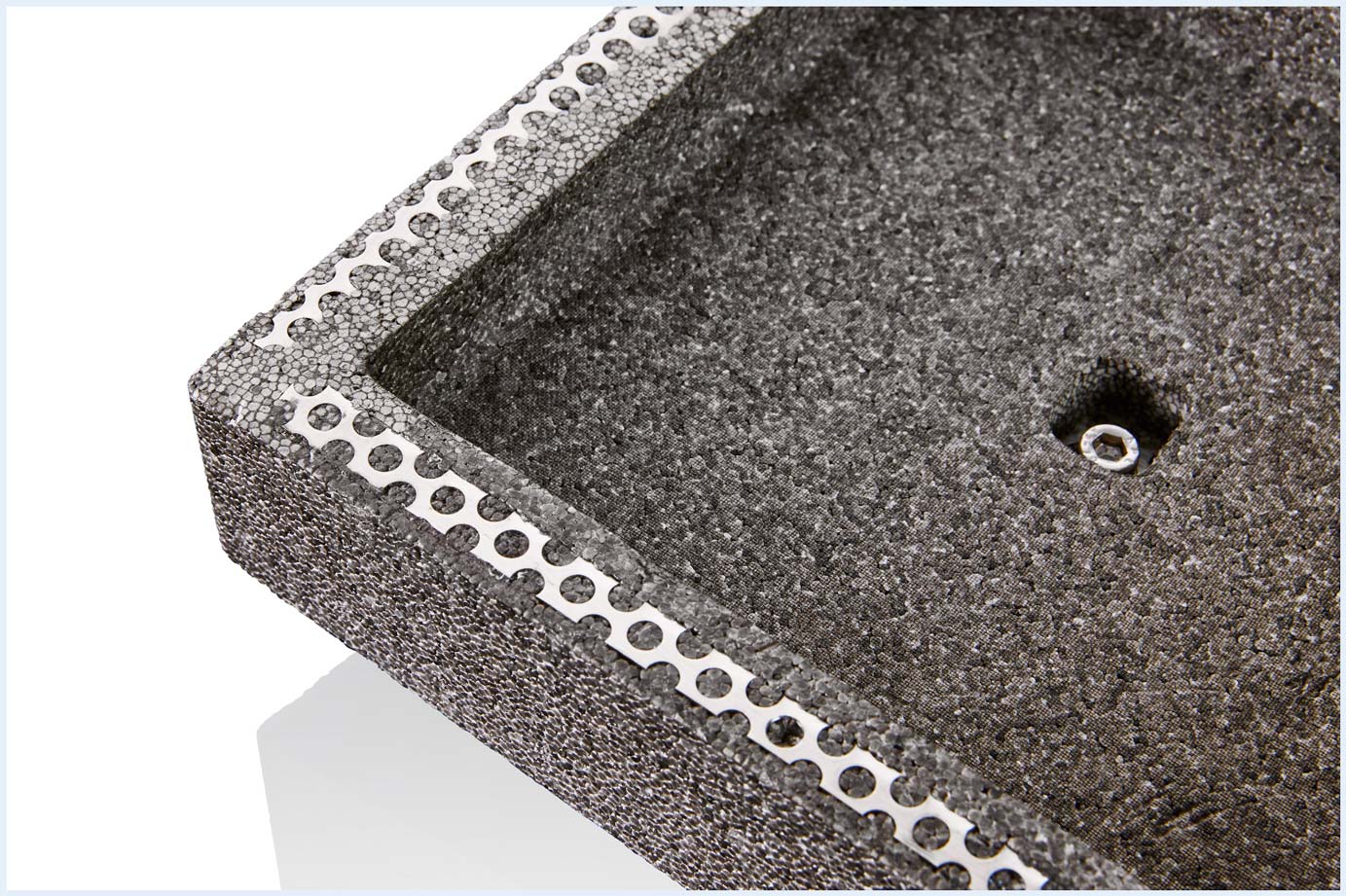

Expanded polyphenylene ether (EPPE) is an innovative, particularly lightweight particle foam with versatile strengths. With its excellent thermal insulation and high temperature resistance, it is ideal for demanding electronic applications that protect foamed-in electronics. EPPE is also used in the mobility sector and in stationary applications – wherever fire protection, precision and low weight are required.

Its flame-retardant properties and excellent flame resistance ensure a high level of safety: EPPE achieves UL94 V-0 classification. In addition, the particle foam enables thin-walled and precise shapes compared to other materials. Another advantage is its high resistance to chemicals, including aggressive substances such as acids and solvents.

EPPE combines lightweight construction, fire protection, insulation and freedom of form

Precise molded parts made of EPPE are used for a variety of applications. Where heat and fire protection play a decisive role, the material often provides the decisive arguments. But EPPE also regularly impresses in terms of insulation and lightweight construction. Here is a selection of application areas:

- Hybrid components with foamed-in electronics

- Components for power electronics

- Lightweight construction parts

- Automotive components subject to the FMVSS 302 standard (Federal Motor Vehicle Safety Standard)

- Safety components, for example in the automotive industry

- Heat-insulating structural components for electronic components

- Heat-resistant housing

- Battery housings in electric vehicles

- Functional components with sophisticated geometries

- Chemical-resistant components

Self-extinguishing particle foam:

the most important properties of EPPE

The self-extinguishing particle foam combines the properties of an ordinary foam with the advantages of an m-PPE (modified polyphenylene ether) and is UL94 V-0 classified. The most important properties of EPPE:

Excellent flame behavior

EPPE is self-extinguishing and achieves UL94 V-0 classification without the addition of halogenated fire retardants.

High continuous temperature stability

Expanded polyphenylene ether remains functional up to a temperature of +120 °C.

Precision/ shape accuracy

Excellent moldability for a wide range of designs.

Good thermal insulation

At a density of 100 g/l, expanded polyphenylene ether has a thermal insulation of just 0.034 W/(m*K).

Suitable for thin walls

EPPE enables thin-walled and precise shaping.

Lightweight construction

Expanded polyphenylene ether is a material with a very low intrinsic weight.

Chemical resistance

The material is resistant to chemicals and aggressive substances such as acids and solvents.

The particle foam based on a modified polyphenylene ether (m-PPE)

The SunForce™ material was developed by Asahi Kasei to meet the growing demands for fire protection, temperature resistance, insulation and lightweight construction in modern applications.

The material is increasingly used in the automotive and electronics industries to dissipate heat from electronic components and thus prevent damage caused by overheating.

Depending on the area of application, suitable material types are available.

More power, more options

- Flame protection: SunForce™ BE is extremely flame-retardant, i.e. the material is self-extinguishing and therefore does not burn.

- Heat resistance: If the molded parts are permanently exposed to high temperatures, SunForce™ BH is the right choice.

EPPE – recyclable high-performance foam

How sustainable a material is depends not only on the raw material, but also on its service life, material efficiency and composition. EPPE is a recyclable high-performance foam with halogen-free flame retardancy and very high temperature resistance with minimal material usage, making it particularly efficient. Expanded polyphenylene ether is REACH and RoHS compliant.

Ready for the recycling loop

As a thermoplastic foam, EPPE can be recycled and reused according to type. Material waste and end-of-life components are shredded, melted down and reprocessed into regranulate. This regranulate can be re-foamed or used as a high-quality technical plastic material.

Thanks to the high thermal and chemical stability of EPPE, the material quality is maintained over several recycling cycles.

All details at a glance

Are you interested in the technical properties of EPPE? Our data sheet provides you with the information at a glance.

Frequently asked questions about EPPE: from the field, for the field

Our FAQ section provides answers to frequently asked questions about EPPE. If you have any further questions, please do not hesitate to contact us personally.

EPPE (expanded polyphenylene ether) is a particle foam based on modified polyphenylene ether (m-PPE). In contrast to classic particle foams such as EPP and EPS, EPPE has a significantly higher temperature resistance, better dimensional stability and – depending on the material type – meets strict flame retardancy standards such as UL94 V-0, making the material particularly suitable for safety-critical applications.

SunForce™ is a high-performance foam developed by Asahi Kasei based on modified polyphenylene ether (m-PPE). Technically, SunForce™ therefore belongs to the same family of materials as EPPE.

EPPE shows its strengths wherever there are high technical requirements in terms of temperature and fire behavior – in battery systems, electronic housings and flame-retardant components.

The recycling process includes sorting and shredding, regranulating, re-foaming and recycling into new molded parts. As EPPE is thermoplastic, the material can be recycled several times without losing much of its properties.

EPP (expanded polypropylene) is a very robust all-round foam with excellent energy absorption, high resilience and very good thermal insulation properties.

In comparison, EPPE is more temperature-resistant and flame-retardant. Furthermore, more delicate geometries are possible.

However, EPP remains the better choice for highly dynamic crash requirements and cost-optimized technical applications.

Yes, EPPE is very easy to foam. In this way, hybrid components with metals, electronics or inserts of various kinds are created in a single production step, for example in combination with battery and electronic components.

EPPE is dimensionally stable up to well over 120 °C, heat-resistant for short periods up to approx. 150 °C and low shrinkage and distortion under continuous load. Depending on the density and material type, the material is therefore particularly useful for high-temperature zones in vehicles or electronics.

Depending on the material type, EPPE achieves UL94 V-0 and is therefore self-extinguishing. It therefore burns with hardly any dripping and low smoke gas development and then extinguishes completely.

Yes, the material price of EPPE is higher than that of EPP or EPS.

Depending on the requirements for the subsequent component, the material is nevertheless attractive and sensible, because the higher material costs are often offset by advantages such as weight reduction and safety requirements that can be met.