EPP: the versatile particle foam for innovative lightweight construction solutions

Expanded polypropylene (EPP) is a versatile, fully recyclable material that is characterized by exceptional properties such as flexibility, high resilience, chemical resistance and excellent thermal insulation properties. With its low weight, high compressive strength and robustness, EPP sets new standards in the field of materials. Whether in house and building technology, head and body protection, medical and analysis technology, mobility or other sectors – the closed-cell material EPP with its high thermal insulation capacity is indispensable in many applications today. Especially when lightweight construction and functional integration are required.

As an experienced EPP manufacturer, we at RUCH NOVAPLAST develop innovative molded parts and housing systems that are precisely tailored to your technical requirements from the particles that are usually supplied in bulk.

EPP impresses in numerous applications for a wide range of industries

EPP molded parts are used wherever flexibility, high resilience and excellent thermal insulation properties play a decisive role. Thanks to our innovations, the material can be precisely functionalized and thus enables individual solutions with a high level of functional integration. Here is a selection of application areas for EPP:

- Lightweight, highly efficient housing systems for heat pumps and ventilation units

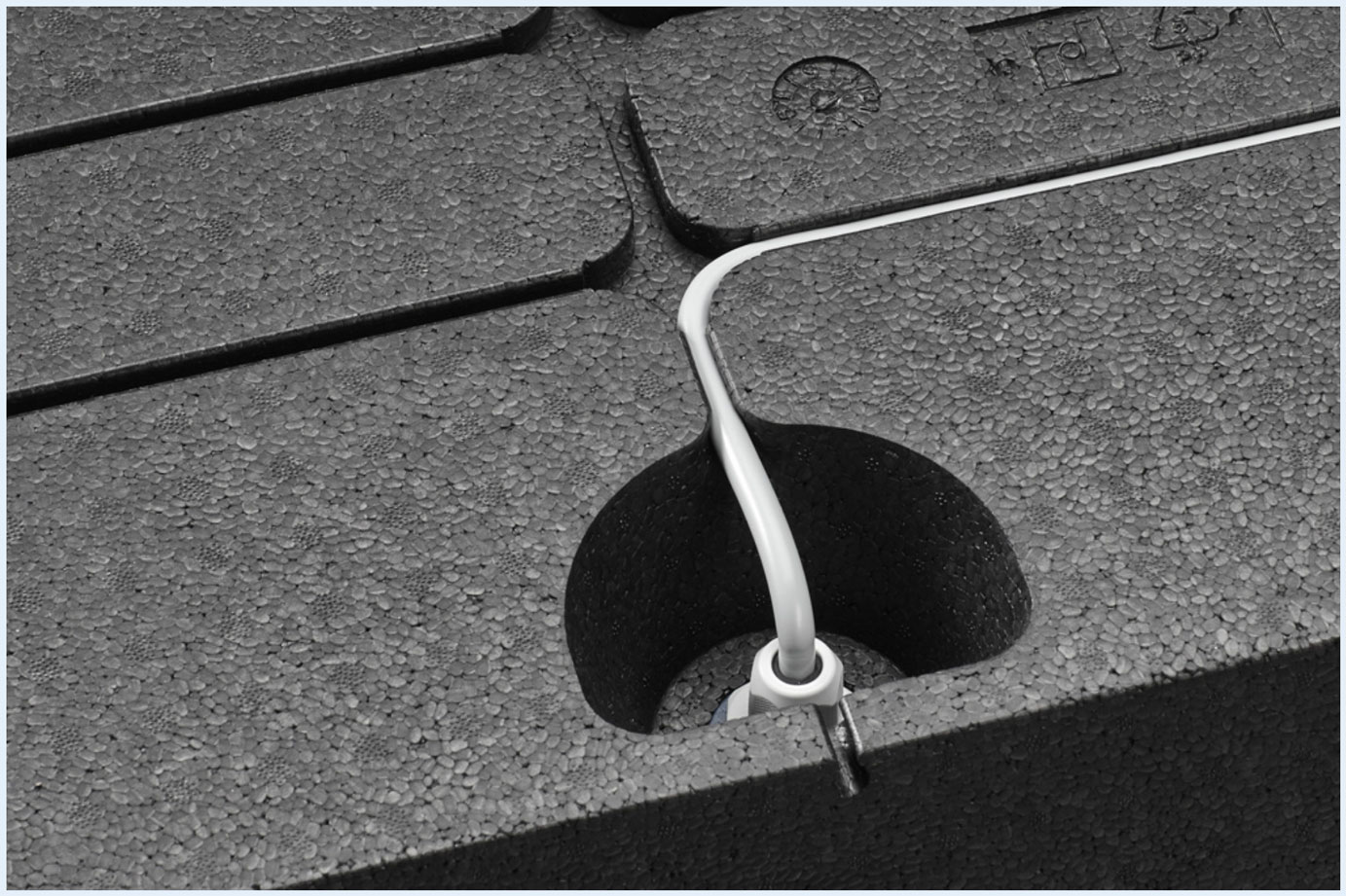

- Air ducts and housing parts

- Insulation parts for heating technology

- Soffit, façade and assembly elements

- Crash elements for helmets

- Protectors for the sports sector

- Chassis for medical devices

- Lightweight structural elements for mobility applications

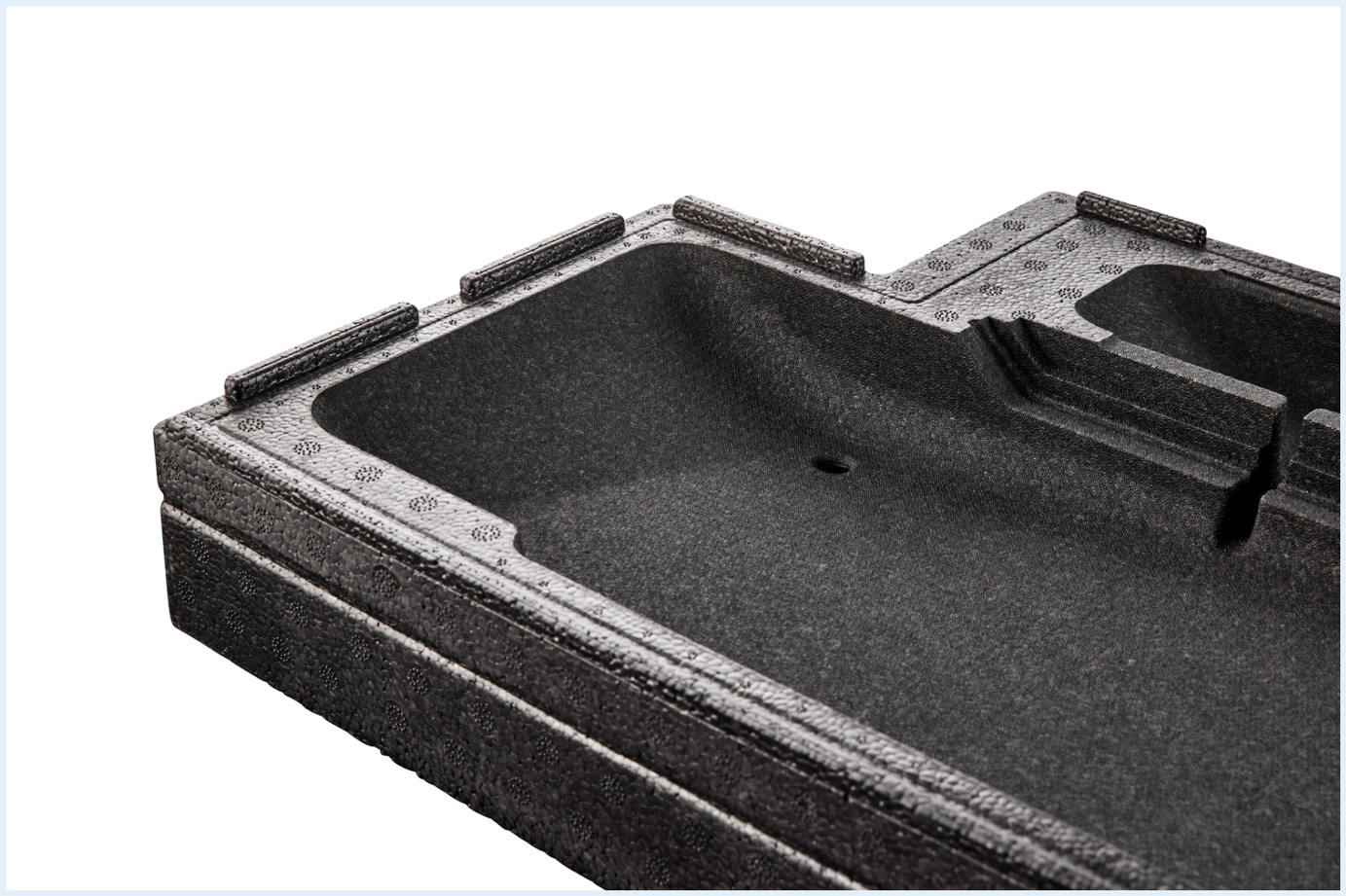

- Insulated transport and reusable containers

- Load carriers for the logistics chain

- Crash pads, bumpers, side impact protection in the automotive sector

- Functional components in the battery housing area

- Design components for the toy industry

- Core materials for sandwich panels

- Insulation materials for heat and sound insulation

Top technical performance with ease:

the most important properties of EPP

Expanded polypropylene stands out from other particle foams due to its numerous physical, thermal and ecological advantages. Thanks to our innovative production technologies, such as the foaming and thermal joining of EPP, we can produce complex components with high precision from this versatile particle foam. Here is an overview of the most important material properties:

Low weight

The particle foam is extremely light and therefore enables energy-efficient solutions in lightweight construction.

Temperature resistance

EPP remains functional even at extreme temperatures – depending on the type, it can be used from approx. -40 °C to +110 °C.

Chemical resistance

The foam is resistant to many chemicals and oils.

Energy absorption

EPP effectively absorbs energy under mechanical stress and protects sensitive components. Even after multiple impacts, the energy absorption remains virtually unchanged.

Resilience

After compression, EPP returns to its original shape under both static and dynamic stress.

Isotropic deformation

EPP exhibits uniform deformation behavior regardless of the direction of impact.

Structural rigidity

Despite its low weight, EPP impresses with its high rigidity and density – essential for load-bearing or dimensionally stable components.

Adjustable density

The density of the molded part can be individually adapted to meet specific mechanical, thermal or acoustic requirements.

Low water absorption

Thanks to its closed-cell structure, EPP absorbs hardly any moisture.

Good thermal insulation capacity

EPP offers excellent thermal insulation properties.

Easy cleaning

The closed surface is easy to clean and sterilize.

Recyclability

EPP is fully recyclable and is produced without chemical blowing agents – environmentally friendly and harmless to health.

For special requirements: Our special EPP materials

Are you planning a project with special requirements? In addition to our standard EPP product range, we also use selected special EPP grades from ARPRO and EPERAN™ PP. We decide what to choose depending on the requirements.

Whether you are looking for even greater stability, special safety standards, color design or more sustainability – our special materials offer you exactly the flexibility you need.

More power, more options

- Higher degree of hardness: For projects with higher loads, we offer EPP with increased molded part density.

- ESD-suitable: Special types protect sensitive electronics from electrostatic discharge.

- Color variety: In addition to standard black, other color variants are also available.

- Flame-retardant: If fire protection is important, EPP is available with flame-retardant properties.

- With recyclate: For sustainable projects, we offer EPP with a defined recycled content from EPP post-consumer molded parts

- UV-resistant: Corresponding special EPP types offer optimized resistance to solar radiation.

EPP as a resource-saving material with a future

EPP not only impresses with its technical properties, but also with its environmental compatibility and its potential for a modern circular economy. As a lightweight material, particle foam actively contributes to the conservation of resources – for example, by enabling durable packaging that can be used several times, reducing transport weight and increasing payload.

Sustainability starts with production

EPP is produced without halogenated hydrocarbons and without the use of heavy metals such as lead, cadmium, mercury or chromium compounds. The material therefore fulfills essential requirements for environmentally friendly production and complies with the principles of the Recycling Management Act.

EPP covers all five levels of the waste hierarchy

- Reduce: The low use of materials and low weight help to conserve resources.

- Reuse: EPP products are durable, robust and can be reused many times.

- Recycling: EPP can be recycled by type. It can be processed into regranulate and used for new products in injection molding or extrusion.

- Energy recovery: If material recycling is not possible, EPP has a high calorific value (over 80 % of crude oil) and can be efficiently recycled for energy.

- Landfilling: Due to the recycling routes mentioned, disposal in landfills is generally not intended.

A material in transition – and in a cycle

If an EPP product is sorted out at the end of its useful life, its service life does not end. It can be shredded, regranulated and processed into new products. The material remains in the cycle – it merely changes its shape. The use of recycled material in the production of new EPP foam beads is also the subject of current research and development, which further improves recyclability.

All details on material properties, special types and sustainability at a glance

Would you like to find out more about the technical properties of EPP? Our data sheet provides you with comprehensive information on material characteristics, special materials, chemical resistance, CO₂ emission factors and environmental aspects.

Frequently asked questions about EPP: understandable, practical, to the point

Our FAQ provides you with answers to the most frequently asked questions about EPP as a particle foam, the molded parts and housing systems made from it and the wide range of possible applications.

Yes – EPP (expanded polypropylene) is a closed-cell particle foam that is particularly lightweight and can withstand high mechanical loads. Thanks to its structure, it returns to its original shape after deformation, making it ideal for a wide range of technical applications.

The material EPP is particularly suitable for such requirements. It provides excellent insulation, is lightweight, noise-reducing and robust. Perfect for applications where the technology inside needs to remain protected and efficient at the same time. Ventilation units made of EPP are a good example: they benefit from its insulating properties and flexible design.

Expanded polypropylene (EPP) is extremely lightweight, yet exceptionally robust and dimensionally stable – even after multiple loads. It offers high energy absorption, is temperature-resistant, water-repellent and chemical-resistant. In short: EPP combines properties that other foams often only offer individually.

EPP is often used in products without you recognizing it at first glance. In everyday life, for example, you will come across it in bicycle or motorcycle helmets, in shock absorbers and protectors, in toys or as an insulating thermal box.

Absolutely. EPP can also be produced economically in smaller quantities.

EPP is extremely durable – and that saves resources. Products made of EPP retain their shape and function even with intensive use and over a long period of time. This means that fewer products need to be replaced and fewer new ones produced. A clear advantage for the environmental balance sheet. EPP can also be recycled and reprocessed as regranulate – for example for new molded parts, injection-molded products or extruded parts. EPP remains in the material cycle and is thus given a second, third or fourth life.

In direct comparison, EPP scores points with its lower consumption of resources during production, better reusability and a closed material cycle. It also requires no blowing agent and is completely free of halogenated hydrocarbons.

A big one. Thanks to its low weight, EPP reduces energy requirements in transportation, for example in logistics or vehicle construction. Its long service life and recyclability also have a positive effect on the overall balance sheet – a real sustainability argument for many companies.

When foaming EPP, a so-called foaming tool is required, which consists of two halves. A hollow chamber is created between the two halves of the tool, which forms the molded part to be produced. The material is filled into the hollow chamber using injector fillers and welded there using steam. The tool is then cooled and the resulting molded part is demolded using ejectors, compressed air or handling systems. This creates three-dimensional molded parts and housing systems that are precisely tailored to your technical requirements.

When thermally joining EPP, two or more molded parts are bonded together using controlled heat. We use this technique to create components that would otherwise be impossible to manufacture.

Very good. EPP is predestined for hybrid solutions, for example in combination with metals, textiles or other engineering plastics. The combination expands the possible applications – for example in automotive or building technology.

EPP offers excellent insulating properties and is therefore used specifically in components for heat recovery systems and heat pumps. It is used there, for example, as a housing material. EPP moulded parts can be designed in three dimensions, reduce energy losses, simplify installation, optimize air flow and safely and selectively discharge any condensate that forms.

Absolutely – Drones made of EPP are characterized by their low weight. The material is therefore also very popular and highly recommended for model making and industrial missiles.

Depending on the application, there are specific fire protection requirements. Special EPP types such as EPP FR, which are flame-retardant, are available for this purpose. This means that even safety-critical applications can be reliably realized with EPP.